Applying the Iron Triangle Model to Contingent Labor Pricing Models

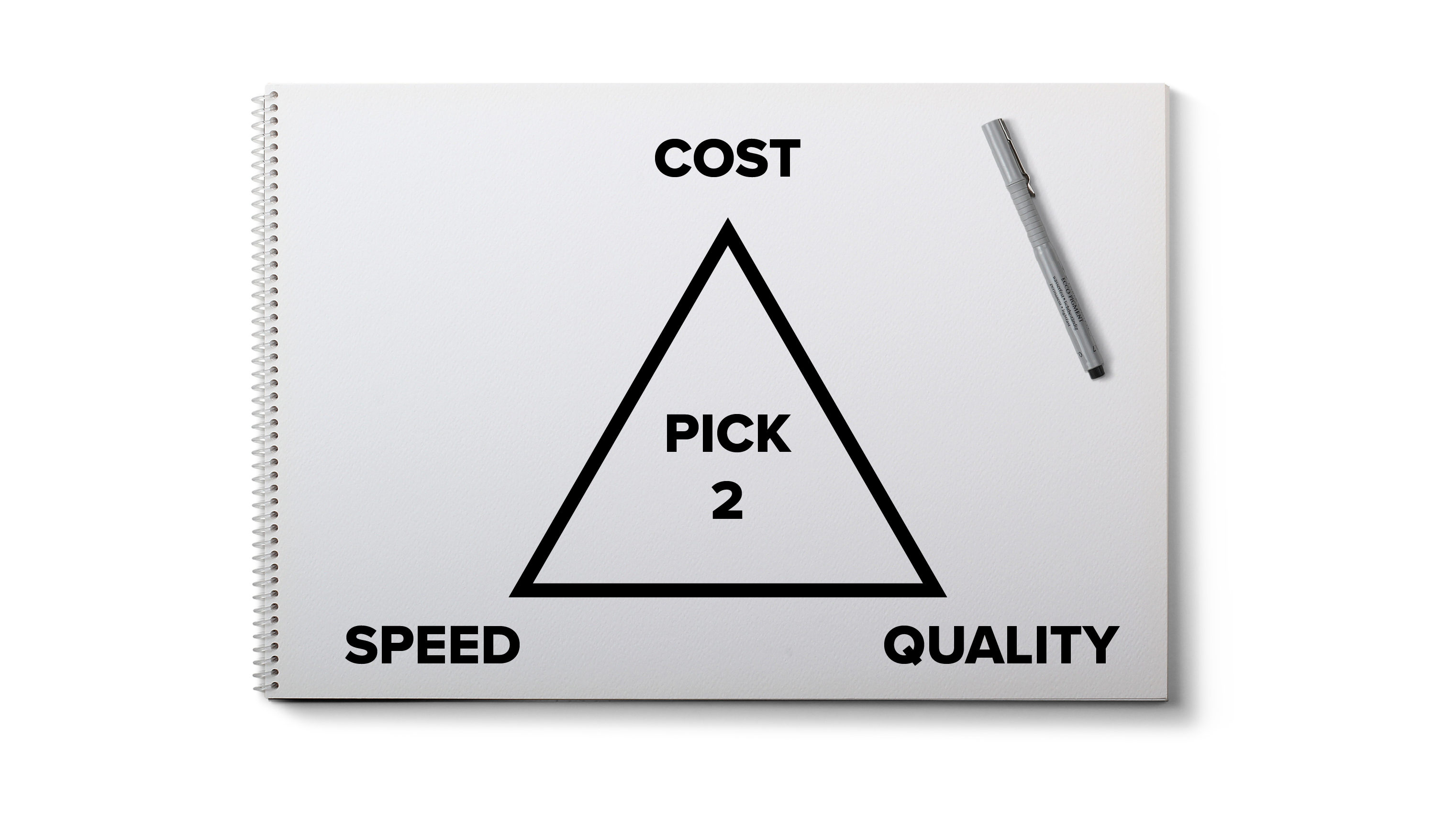

My brother-in-law is a general contractor. When customers ask him for pricing quotes on home improvement projects, he often points to a sign in his office that states, “We do work properly, quickly, cheaply—pick 2.” The implication is, if done quickly and cheaply, proper process is not likely to be observed. If work is done properly, but cheaply, it may take longer to accomplish, and if you want it done properly and quickly, it will cost a premium. This triad model is sometimes referred to in a more serious business environment as the Iron Triangle, and here’s how you can apply its wisdom to contingent labor pricing models.

The Iron Triangle, like my brother-in-law’s sign, holds that the quality of any work must observe three constraints: scope, cost, and schedule. A contingent workforce project manager must always seek balance between these three factors and know when and which to sacrifice in any given situation. Changes to any one constraint will always require associated changes within the remaining two in order to compensate. For example, you can have it [candidates] fast, but the scope will have to be smaller. Conversely, if you wait a bit longer, you’ll be able to include the entire scope in your process. The same triangular model can be applied to cost constraints for contingent labor. Substitute “pricing competitiveness” for “quality” in the iron triangle and the same three constraints apply the same.

Consider the “scope” requirement in terms of volume of spend and headcount. Is the program managing $5M in annualized spend or $5B? Is the headcount closer to 100 workers or 100,000? Clearly, the company with $100M scope will be able to negotiate better terms than the company with only $10M to spend.

Consider the “cost” requirement in terms of discounts levied against suppliers. What are the administrative fees for your program? Are volume or overtime discounts offered? Are costs incurred by background checks assumed by the supplier’s margins or billed back to the customer? Providing too many discounts will impact a supplier’s profitability and can negatively impact their ability to provide sufficient talent.

Consider the “schedule” requirement in terms of labor market dynamics. What skills are required to serve your program? Are you seeking to fill non-skilled labor roles or high-level, highly-specialized, in-demand roles? What is the availability of talent with the desired skill sets in your locality? Obviously, hiring in locations like Yuma, AZ or Ocean City, NJ where April unemployment was at 15% and 11%, respectively, is a much different experience than hiring in Madison, WI or Nashville, TN where unemployment is at 1.9% and 2.2%, respectively.

Given these constraints, how can pricing models be set to ensure timely access to appropriate talent at reasonable cost?

Gain rate buy in from suppliers on what their cost should be given the constraints above. If the supplier uses a markup structure, have them propose costs and agree to fixed terms for two or three years with a commitment to revisit terms as the labor market or unemployment rates change. If using rate cards, have suppliers bid on the rates to support the roles, with clear understanding that there will be exceptions and changes required for deviations from the standard job descriptions.

Identify cost savings through other efficiency gains in the program such as, consolidated invoices, sourcing efficiency, and discounts for referred workers. Cost savings should be measured against what the market is, not against historical costs or spend levels. If the market is showing a $40.00 bill rate for a junior graphic designer in Philadelphia, but two years ago, you paid $35.00, placing someone at $38/hour should be a $2/hour saving measurement not a $3/hour increase.

Identify alternate supplier partners. Source and locate partners who are able and willing to grow and change with your organization. nextSource focuses our relationships on increasing the business of our supplier partners so they might better leverage discounts and market intelligence. In the past 24 months, nextSource has increased spend with its top 20 supplier partners by 83%, delivering increased fulfillment, reduced fill times and greater opportunities to measure cost savings compared to the market for all nextSource customers.

What companies shouldn’t do: Focus on cost savings above access to talent. If your competitor down the street is paying $1.00 per hour, and the supplier has a better profit margin to place their talent there, your job openings will go unfilled. The procurement of talent is being over commoditized, without consideration for suppliers increased costs and in a very challenging labor market with intense competition. Protect supplier relationships! Before you let go of a supplier due to its unwillingness or inability to meet your terms, revisit the negotiations and try to find a balance using the Iron Triangle as your guide.